Summary

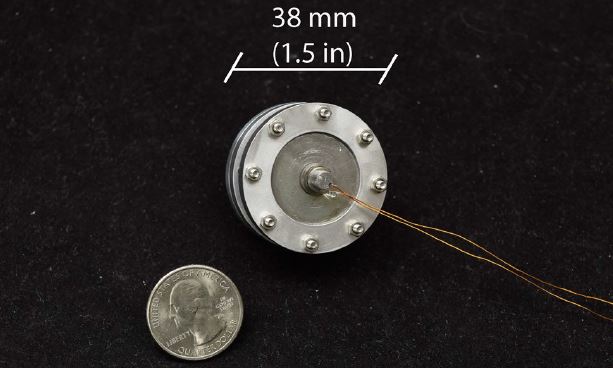

A team of Vanderbilt engineers have developed a miniature magnetorheological (MR) brake with a combination of high braking torque and a fast response time (see Fig. 1 for size). With potential applicability over a wide spectrum of applications, the device was initially developed with robotic and haptic applications in mind.

Addressed Need

Meeting the torque and response times demanded from MR Brakes within the confines of available space is challenging in currently available MR Brakes. This is especially true for robotics, where a smaller and lighter brake in each joint would lead to better dynamic performance without compromising available torque. Small, light brakes with fast response are similarly important in haptic applications, because the human sense of touch is so sensitive. The current MR Brake technology provides the largest torque-to-weight ratio and more than twice the braking torque compared to similarly-sized MR brakes currently available. The inventors are not aware of any MR Brakes commercially available at this small size.

Technology Description

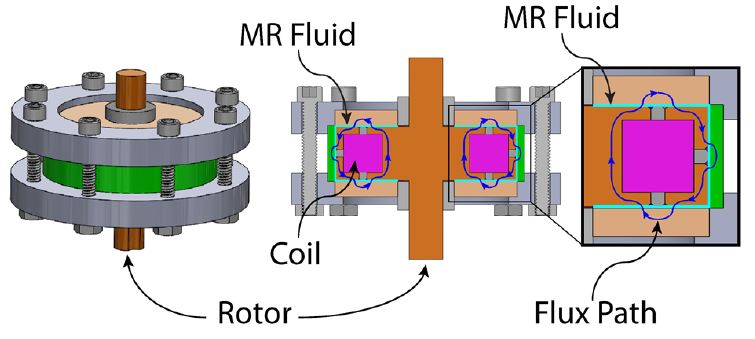

The amplification of braking torque in this MR Brake design lies in the utilization of all three shear surfaces surrounding the rotor. This is accomplished by the combination of the placement of the current-carrying coils in the rotor (rather than the housing) and the increased crossovers (six rather than the convention two) of the magnetic flux path through the MR fluid gap.

Technology Development & IP Status

- Prototype device constructed

- Testing underway (partially completed) in a haptic mechanism for robotic bone-milling

- Published patent application: WO 2020/163203

- Journal publication: imminent

Opportunity

We are currently seeking a partner for commercializing this product for various applications.

Figure 1: The size of the actual MR brake compared to the size of a US quarter.

Figure 2: CAD drawings of two different views of the MR brake assembly: Left) Assembled view, and Right) cross-section view. The electromagnetic coils are colored purple within the mild steel rotor, colored orange. Aluminum rings, colored grey, are embedded into the rotor. The outer housing consists of a stainless-steel ring shell, colored green, and two endcaps, colored pale orange. The entire housing is held together by two aluminum end pieces, which are secured with eight bolts that surround the assembly.