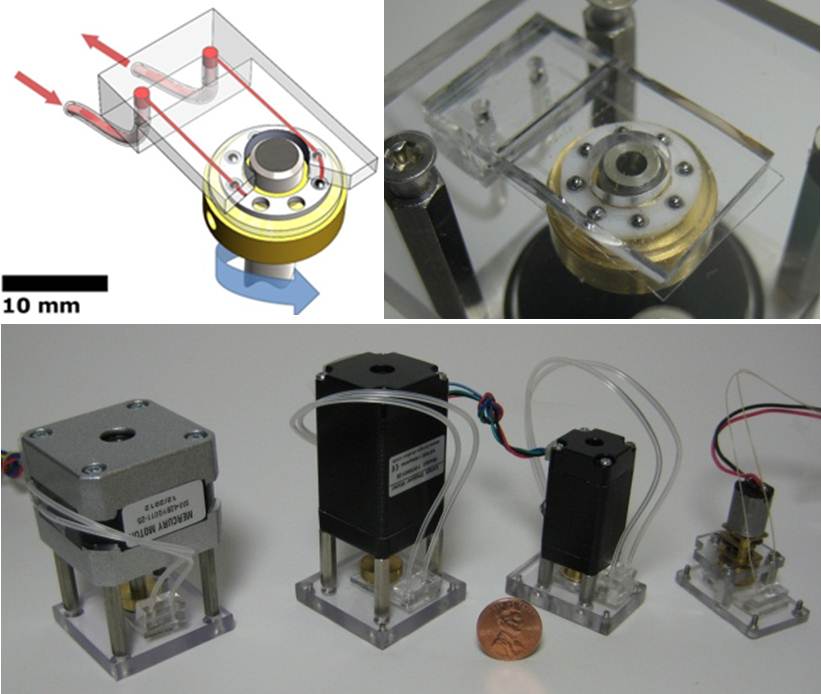

Sometimes, you just need to be in the right place at the right time. That was certainly true for Matt Gevaert, CEO of KIYATEC, Inc. After a chance meeting at a national conference with David Merryman of the Biomedical Engineering department at Vanderbilt, Gevaert found himself in Nashville on a personal trip and decided to reach out to Merryman. During that visit, Merryman thought to connect Gevaert with a fellow Vanderbilt professor, John Wikswo, Ph.D., who had been working on a technology that seemed to be a good fit for KIYATEC. That technology, a system of low-cost, small-volume, metering peristaltic micropumps and microvalves, exhibited many of the capabilities that KIYATEC needed to achieve his company’s core mission – to accurately predict cancer patients’ response to drugs using live 3D cell culture models.

"The culture of cells in 3D, initially promoted by cancer biologists and tissue engineers, is catching on in the larger biological and drug development communities - heterogeneous cell populations growing in 3D matrices are seen to behave quite differently than monolayer monocultures on plastic, the current standard,” said Wikswo. “Our pump and valve technology is ideal for small-scale 3D tissue culture, in that it will enable low-cost, low-volume, recirculating perfusion and fluidic control in a way not heretofore possible. I expect that drug development, environmental toxicology, biodefense research, and systems biology will all benefit."

Merryman’s instincts were right on the money. Wikswo is a nationally recognized thought leader in the “organs-on-a-chip” field, with funding from the NIH, DARPA and EPA to advance miniature models of living organ tissues on transparent microchips in which pumped fluid is imperative. He and Gevaert saw an immediate fit.

"Kiyatec's ongoing cancer studies that will benefit from these pumps is perfectly aligned with the rapidly growing interest in "you-on-a-chip" for personalized medicine," said Wikswo.

Wikswo’s expertise in the field and the power of this technology led KIYATEC license the pump technology from Vanderbilt. They are now moving forward with commercialization plans.

“We pump media (fluid) through our cancer models – this kind of ‘dynamic’ flow has many advantages over ‘static’ or still media culture, especially for longer duration experiments,” said Gevaert. “There is often a trade-off between perfusion (higher functioning, better models) and throughput (ability to generate many results in parallel). What interested us specifically about Dr. Wikswo’s technology was the potential to mitigate this trade-off; it will enable us to powerfully and cost effectively increase the throughput in our perfusion cultures. That will translate to a bigger impact on cancer patients by giving their doctors more drugs evaluated in each test we run.”

Gevaert says they will also explore the potential use of this technology in academic research settings – where researchers are working to develop new 3D cell culture models, namely cancer models and those for drug screening, which KIYATEC might one day also in-license.

KIYATEC plans to first develop stand-alone micropumps that can automate and reduce the size of flow-based cell cultures. These pumps will be used internally for 3D cancer drug screening and the creation of 3D cancer models, which Gevaert hopes will assist in the offering of more personalized therapies. Looking into the future, Gevaert expects that the company will be co-developing micropump and valve systems with partners as another product line for the company.

"KIYATEC's strategy of first developing pumps for their internal use is very clever -- their first customer will be very loyal and will deliver immediate constructive feedback when the inevitable glitches are encountered,” said Wikswo. “They are off to a very good start in that they are already working on a very important yet hard biological problem and need our technology."